The construction industry, one of the world’s oldest and most essential sectors, is in the midst of profound change. For years, builders have grappled with stubborn challenges: labor shortages, pressing deadlines, rising costs, and persistent safety risks. According to recent reports, nearly 80% of construction firms struggle to find qualified workers, and jobsite injuries remain among the highest across all industries. These numbers aren’t just abstract—they reflect real, daily pressures experienced by companies, workers, and clients everywhere.

Robotics in the construction industry is emerging as a timely, robust response. Whether it’s demolition robots making dangerous tasks safer or 3D printers streamlining the creation of concrete structures, construction robots are stepping in to ease familiar headaches and uncover new opportunities.

Of course, with such profound technological shifts—especially in a field so rooted in tradition and skill—it’s natural to feel both excitement and uncertainty. What will these changes mean for the people onsite? In this blog, we’ll explore how robotics in construction is reshaping not just the way our buildings rise, but how the people behind them can thrive in safer, more innovative, and more sustainable workplaces.

What Is Robotics in Construction?

Robotics in construction involves the use of advanced machines, often guided by computer systems, sensors, and even a bit of artificial intelligence, to assist or perform tasks on building sites. These are not science-fiction humanoid robots, but rather specialized “construction robots” built to make life easier, work more efficiently, and make sites a bit safer.

There are multiple tasks that these robots handle. For example:

- Demolition Made Safe: Demolition robots are remote-controlled machines that safely tear down walls or break apart old concrete.

- High-Speed Bricklaying: Bricklaying robots can lay hundreds of bricks an hour with incredible precision, reducing physical strain on human masons.

- 3D Construction Printing: 3D printing robots can “print” entire concrete structures layer by layer. These are being used to build everything from single-story homes to bridges.

- Drones in Construction: Drones can map terrain, monitor project progress, inspect hard-to-reach spots, and collect data that helps keep construction running smoothly and safely.

All of these examples are united to solve real-world construction challenges by blending human ingenuity with technological power. Robotics is creating a smarter, safer, and more collaborative environment where both people and machines can contribute their strengths. As we see more of these robots, it’s clear they’re here to help skilled workers build better, together.

Why Is Robotics Becoming Important in Construction?

While worker shortages dominate headlines, an even starker reality is emerging. In 2025, U.S. construction firms are estimated to be short by as many as 650,000 workers, putting enormous pressure on project delivery. This gap delays and increases costs because skilled workers are simply unavailable for critical tasks at crucial times. A recent white paper reveals that 94% of construction firms report being unable to fill open positions, and worker retention remains a significant challenge, driving costs even higher.

Robotics in construction is stepping up precisely to close these gaps. By automating repetitive or hazardous work and optimizing jobsite operations, construction robots help projects stay on schedule, improve quality, and ease the immense pressure on human crews. As a result, companies can complete ambitious builds without being at the mercy of labor market fluctuations. This not only benefits contractors but also makes buildings safer and timelines more reliable for everyone involved.

Key Types of Construction Robots

As robotics becomes more integral to modern building sites, each robot is designed to meet specific needs. Let’s break down the most important types of construction robots you’ll see in the industry today, and what they actually do on-site.

Bricklaying and Masonry Robots

These robots automate the painstaking task of laying bricks or masonry blocks, which is traditionally labor-intensive and repetitive. This acts as a machine that works alongside human masons, placing bricks and spreading mortar with steady, mechanical precision. This speeds up the building process and ensures that every brick is laid evenly.

The SAM100 (Short for Semi-Automated Mason) is one such robot, already used on many U.S. sites to lay thousands of bricks per day, reducing physical strain on workers and boosting overall productivity.

Demolition Robots

Designed to take down structures and handle hazardous demolition work with greater safety and efficiency. These are remote-controlled machines sent into unsafe or hard-to-reach areas to break down walls and concrete. One prime example is Husqvarna’s DXR line of demolition robots, which is well-known in the industry for frequently demolishing interiors or hazardous spaces where it’s unsafe for humans to go.

3D Printing/Concrete Printers

This type helps to “print” buildings and structural elements directly onsite or in factories, by layering concrete or other materials according to digital blueprints. It utilizes a computer model to create shapes that would be difficult or expensive to build by hand. An innovative startup, ICON, has used its 3D printers to build affordable homes in Texas, crafting full-size houses in just a matter of days.

Surveying and Inspection Drones

Drones are like flying robots equipped with cameras and sensors, buzzing over job sites to create aerial maps, check progress, and quickly spot potential issues, saving countless hours compared to ground surveys. The primary purpose is to map, monitor, and inspect construction sites from above, gathering real-time data and images.

Robotic Arms for Prefabrication

These are industrial robots you might find in a car factory, but adapted for construction. They work tirelessly to make walls, modules, or beams with accuracy and speed, ensuring every piece fits perfectly together when it’s delivered for assembly. Many leading precast concrete companies now rely on robotic arms to produce panels and modules, helping ensure consistency and freeing up skilled workers for more complex onsite tasks.

With these technologies, robotics in the construction industry is rapidly changing the way projects are planned, executed, and delivered.

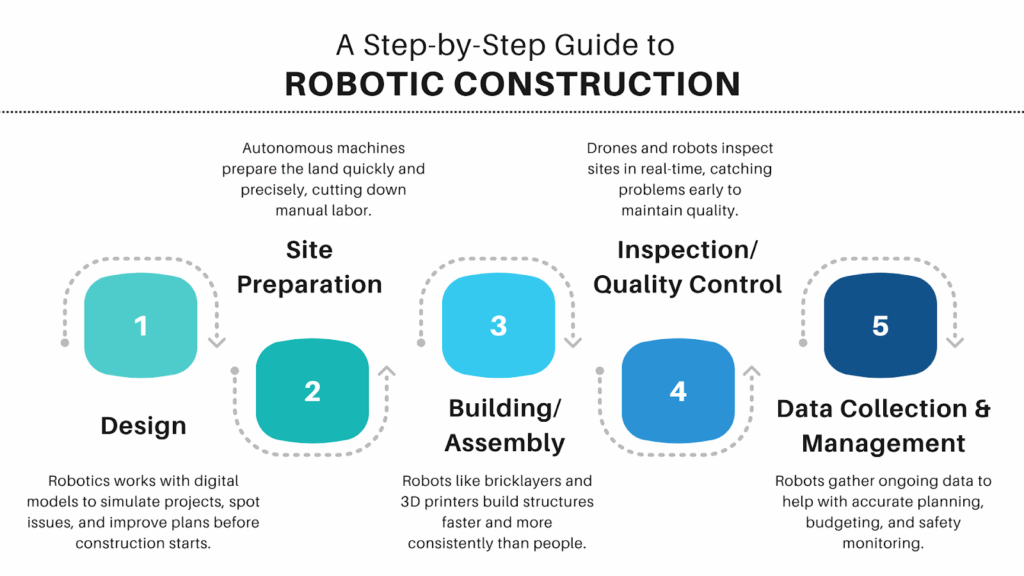

How Robotics Is Transforming Project Workflow

As robotics carves out its place on construction sites, it isn’t just the tools and tasks that are changing. Let’s walk through how robotics is streamlining each phase of a typical construction project.

Robotics and artificial intelligence are playing an increasingly vital role in construction by helping teams create more accurate timelines and budget projections. When it comes to productivity, robots can work tirelessly around the clock, handling multiple repetitive jobs simultaneously and maintaining a steady, consistent pace. This capability significantly speeds up project completion and minimizes costly downtime.

In terms of accuracy, machine-controlled processes ensure reliable, repeatable results, leading to less rework and higher-quality buildings. Perhaps most importantly, robots take on dangerous jobs such as demolition or inspections in hazardous areas, dramatically reducing workers’ exposure to risks and improving overall workplace and site safety.

Ultimately, robotics in construction is setting new standards for efficiency, precision, and safety across the industry.

Benefits of Robotics in the Construction Industry

As robotics continues to find its footing in construction, the advantages these machines bring are becoming impossible to overlook. Let’s take a closer look at some of the key benefits that construction robots contribute to the industry.

- Improved Safety for Workers: Robots take on dangerous or repetitive tasks—such as demolition or heavy lifting—reducing the risk of injury and keeping human workers out of harm’s way.

- Increased Efficiency and Speed: Construction robots work tirelessly and consistently, enabling projects to progress faster and meet tight deadlines with greater ease.

- Higher Precision and Quality Control: Automated machines deliver exact, repeatable results—whether laying bricks or assembling components—leading to stronger, more reliable structures.

- Reduced Long-Term Costs: Although the initial investment can be substantial, robotics reduces overall expenses by lowering labor costs, minimizing errors, and minimizing rework.

- Environmental and Sustainability Benefits: Robots optimize material use and reduce waste on site, supporting greener construction practices and helping the industry lessen its environmental footprint.

Together, these benefits show how robotics in construction is about building a safer, brighter, and more sustainable future for everyone involved. While robotics in construction brings impressive benefits, it also comes with its share of hurdles.

Challenges of Robotics in the Construction Industry

As with any technological shift, it’s essential to recognize the obstacles that companies, workers, and the broader industry may face in adopting these innovations. Addressing these concerns openly helps ensure that progress is both practical and inclusive.

- Initial Investment/Cost Concerns: The upfront costs of purchasing, deploying, and training for construction robots can be significant, especially for smaller firms or projects with tight budgets.

- Change Management and Adoption Among Workers: Introducing robotics means changing how teams work. There can be understandable resistance from workers who may feel uncertain or hesitant about learning new systems or adjusting to new processes.

- Job Displacement vs Job Evolution: While new tech can create opportunities for upskilling and job evolution, it may also displace some traditional jobs, making it crucial to support workers through the transition.

- Technical Limitations/Maintenance: Robots can break down, require specialized maintenance, or struggle with unexpected onsite challenges that humans might easily solve, highlighting the need for ongoing technical support and adaptation.

By acknowledging these concerns, the industry can better plan for a future where robotics empowers people, boosts productivity, and helps everyone adapt to the new landscape of modern construction.

Conclusion

As we’ve explored together, robotics in construction is all about high-tech gadgets, futuristic assembly lines, and, most importantly, about people. These innovations are helping make our worksites safer, our buildings stronger, and our days a little bit easier. It’s natural to have some questions or even a few worries as new technology arrives on-site. But remember, construction progress has always been about adapting, learning, and working together. When we embrace these advances with curiosity and a collaborative spirit, the future looks excitingly full of possibilities.

So, whether you’re a builder, a designer, or simply someone fascinated by how our world is made, keep asking questions and stay open to change. The journey of robotics in construction is just getting started, and there’s so much more to discover. By combining human know-how with intelligent machines, we’re building a better way forward, together.